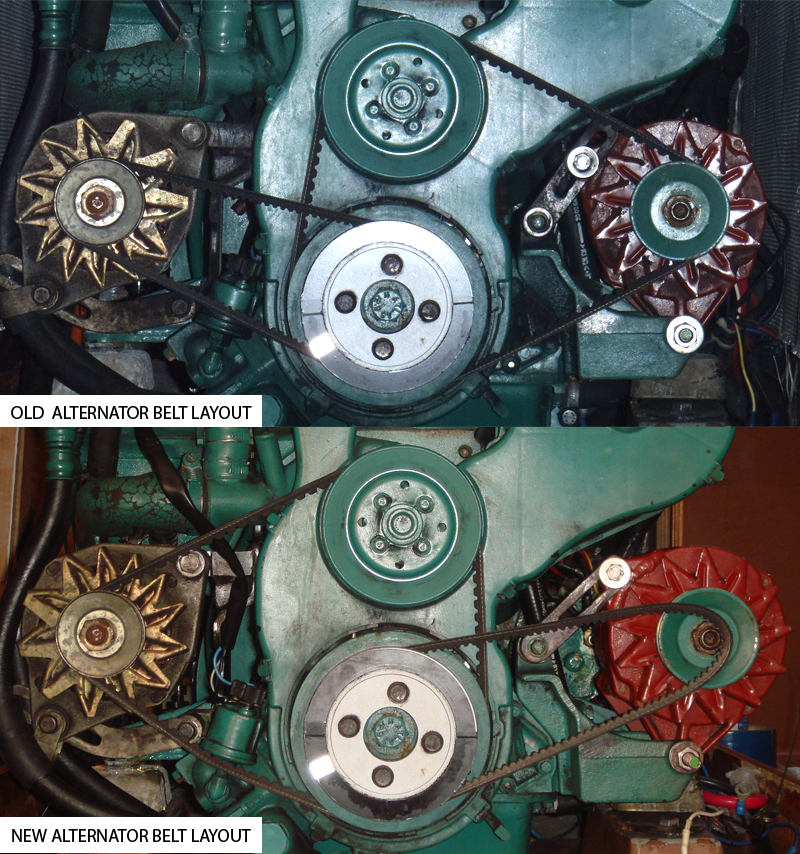

I've just changed my Alternator Belt Layout, see picture:

Reasons for doing this:

The 12V alternator (on RHS of picture) is 120A, and gets through (9mm) belts quite quickly. The other belt (24V alternator) has not been changed in 10 years.

The load on the 12V belt was increased by being shared with the water pump.

The new layout reduces the load on this belt, and increases the wrap on the pulleys.

The drive spindle is now slightly smaller, so again this should reduce slippage.

Now I need to measure for new belts:

I was thinking of using some 3mm string with the alternators where I want them to end up, will this work?

How much movement of the pulley should I allow to fit the belts?

The more observant of you will have noticed a problem with the oil pressure sender, more on this in this thread:

http://www.bavariayacht.info/forum/index.php/topic,962.0.html