My original fuel lines had metal braid covers, which were badly corroded where they go through the bilge into the aft cabin. Insurance wanted them replaced, and also a fuel shut-off valve added (the boat never had one, although there were holes in the bulkhead where it would've been).

Additionally I wanted to replace the CAV filter, which has previously caused furious anger and spilled fuel when the bolt that holds the contraption together refused to engage. What I wanted was a Racor 500FG, because the filter change there requires no tools and the fuel stays in the housing, which works like a bucket with a removable lid and the filter is inserted in the top. I thought if I ever had to change filters at sea I would definitely not manage it with the hateful CAV contraption.

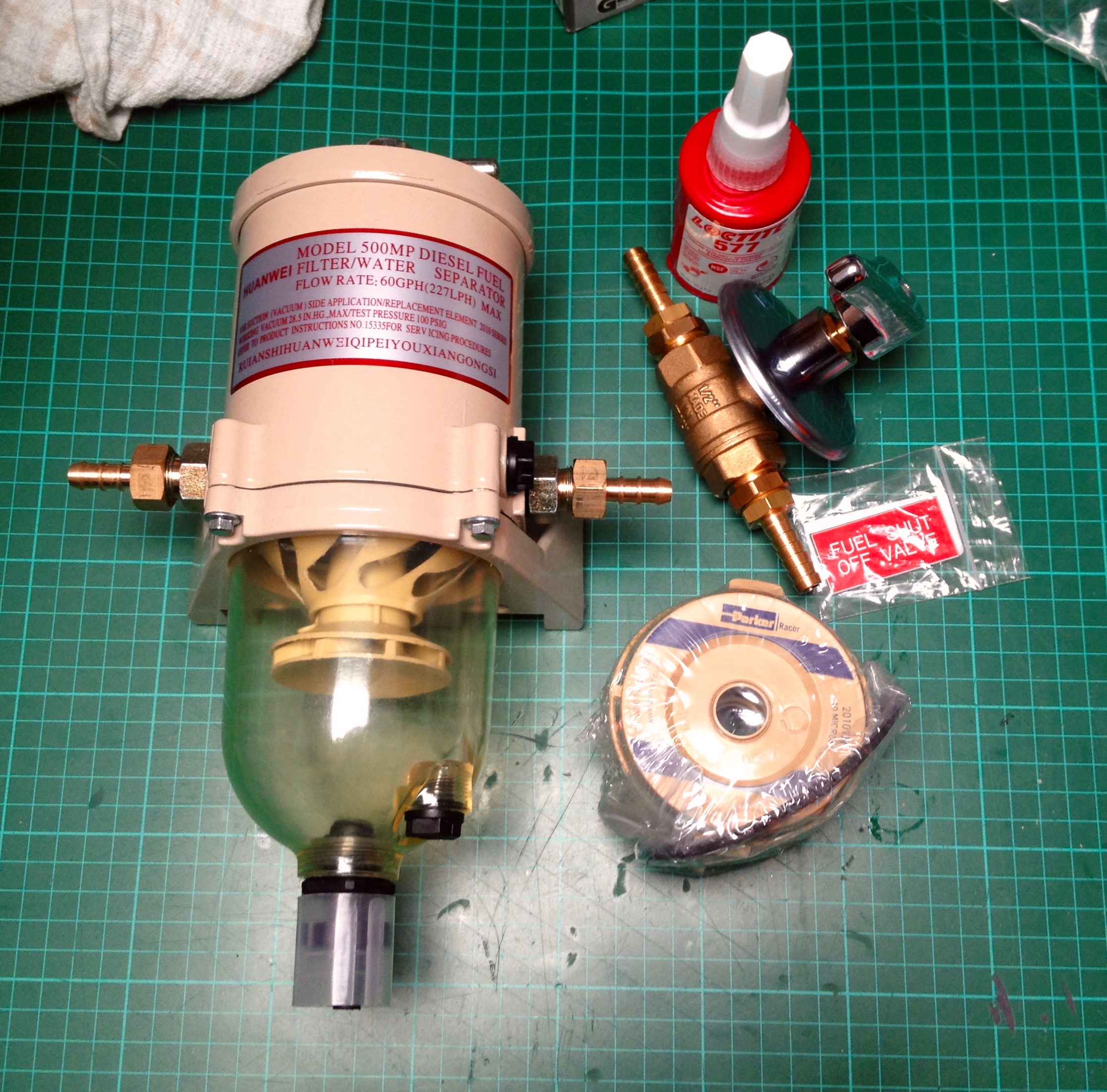

Alas, the Racor had what I considered unreasonable pricing for a bit of cast metal and some plastic bits. Luckily I found a

Chinese copy of it on Amazon for a much more reasonable price. I ordered it, took it apart and looked for quality issues. There were some minor edges from casting, which I smoothened and all the O-rings were of abysmal quality, so I replaced them from the

onboard o-ring kit. Took about half an hour all together. Unlike the Racor, this Facor also came with UNF to BSP adapters and (90°) hosetails for 10mm OD hose. All the thread sizes seem to be exactly the same as the Racor, so you can use Racor parts, fittings and add-ons (e.g. the vacuum gauge or the water alarm). I also threw away the crappy paper filter cartridge it came with and inserted one of the Racor ones I'd stocked up on (original ones, under £5 per cartridge).

For the fuel shut-off valve I wanted a bulkhead valve, so it can be operated without first taking the aft cabin bed apart to access the tank fittings. The local chandlery sourced one from one of their suppliers (Aquafax I think), but the only one they could track down was a bit large, so I also got some reducers and hosetails for both sides. Assembled all of this with Loctite 577 fuel-resistant thread sealant. ASAP supplies even had a nice label plate for it.

With the help of

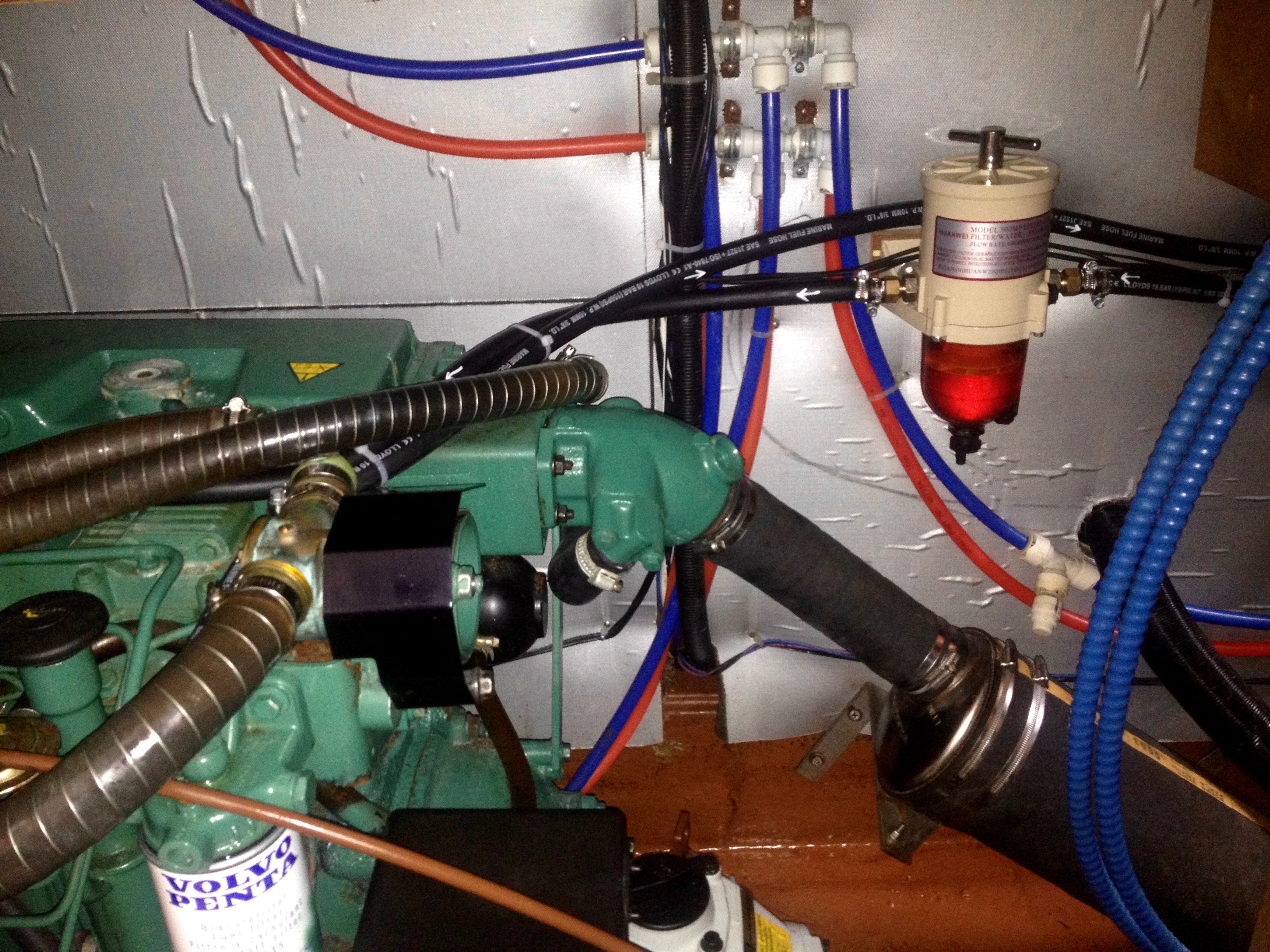

Nigel's shopping list I've ordered the tank fittings needed, plus straight hosetails for the Facor as it would've looked silly with the supplied angled ones. On the engine side there were already hosebarbs, which I've reused (after unscrewing them, cleaning up and applying new thread sealant).

I took out the tank pipes, which interestingly where both the same length (to the bottom of the tank). I expected the return one to end at the top, but it doesn't really matter much. The old cutting ring (different from compression rings, also known as olives, see

this illustration) fittings had bitten deeply into the pipe and needed to be sliced open lengthwise with a Dremel cutting disc and then split to be removed. I then sawed off the ridged end where the cutting ring had bit into the pipe, losing me only 2mm length on each pipe. If there is enough length to spare, just sawing it off after the cutting ring is a quicker way to get rid of it all. Then applied the compression ring (olive) fittings and put the pipes back into the tank.

Pulling out the old hose made a big mess, as the rusted metal braided cover was no longer flexible and crumbled into showers of rust flakes. I ended up cutting it in parts with a big wire cutter and pulling it out in pieces, catching the fuel with an oil drain pan and lots and lots of

oil absorbing pads. They're pretty good for wiping the rust flakes and accumulated dirt out of the bilge, especially once soaked in diesel fuel, which is a pretty good solvent that won't attack the bilge paint.

Hoseworld supplied the new 10mm ID marine fuel hose, all rubber, no more rusting braid. This is a very thick walled hose, of which I needed 10m total (£34 total). I laid the hose out straight in the cabin, then found the middle and put it at the engine, pulling both ends aft together. Everything on my 40 Ocean was wonderfully accessible, except the area where it goes from the bilge into the under-bed tank area - someone had installed large hot air ducts for the Eberspächer there. Managed to pull the new hose in with a bit of gymnastics. Connected it to the tank fittings and shut-off valve and mounted the house on bulkheads with some blue plastic clips (20mm) from Toolstation, working my way forwards from the tank, always marking the hoses with supply and return arrows so I don't lose track of which is which.

Once I reached the engine, I marked and cut the hose loop with a cutting board and sharp knife, then closed the shut-off valve and blew into each hose to confirm I had marked them correctly (the one with the closed valve would not be possibly to blow into, the other made bubbles in the tank). I'd also removed the CAV filter and drained it, and drilled the mounting plate to re-use it for the new Facor filter. While taking the CAV filter apart I noticed why it had given me such grief before - the top rubber sealing ring was actually two seals stuck together, and thus the whole stack ended up being too thick for the bolt to engage easily. Derp!

Hooked up all the hoses except the one from the filter to the engine, which I left disconnected at the filter. There I then connected a small portable 12V pump used for sucking old engine oil out of the engine, which did a wonderful job of priming the fuel system. As it flooded the filter, you could see the turbine working (which you don't see once it's full of fuel). This took mere seconds, after which I removed the pump and installed the engine fuel hose on the filter, then cracked the bleeding screw on the engine and bled the remaining air out of the hose using the lift pump.

The engine started at once and did not stutter (the MD22 generally seems to be quite good with that - it has always started with a bit of air in the pipes even when I'd cracked the old fuel lines at the tank to measure the fittings). I left it running for a while, whilst checking for leaks and looking for any air bubbles in the filters transparent bowl, neither of which I found

After a few engine hours I'll also replace the engine fuel filter, which should contain any debris introduced in this undertaking.

Ingmar