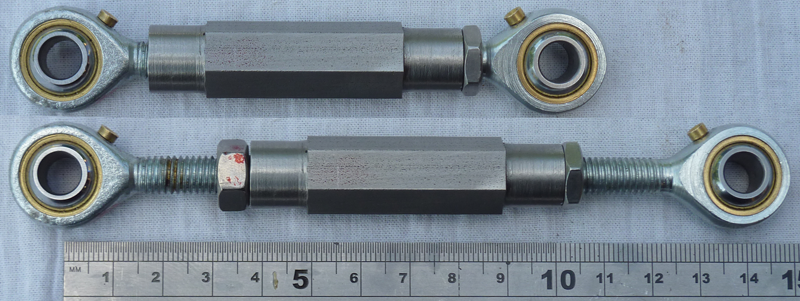

I've realised that I haven't posted details of the Alternator Adjuster I made from M8 track-rod ends and some 18mm stainless hex bar. Note that I used 18mm as the nuts are 17mm. This is the same adjuster at the two extremes (I use half-nuts both ends):

Complete installation details below.

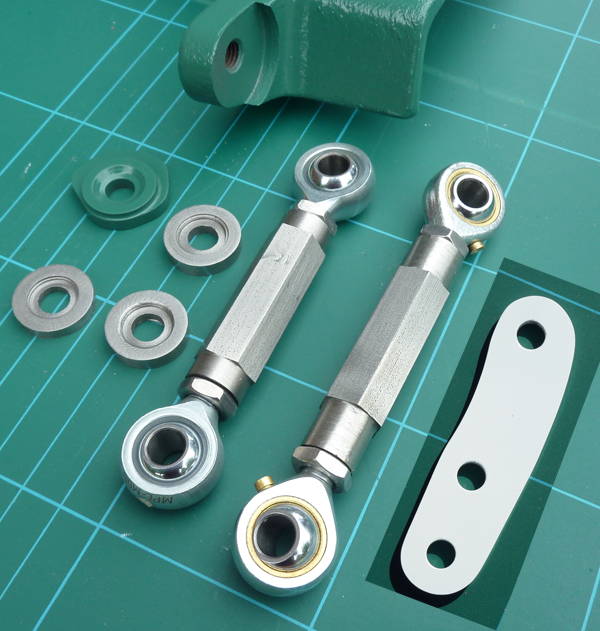

Some of these bushings are just to convert from 1/2" to M12, some to make an M12 screw thread a bit tighter in a reamed 12mm hole (aluminium drink can, 0.1mm). There are two bushings for the green bracket, one with an offset centre:

Adjusters and spacer washers, plus an insert of the bracket:

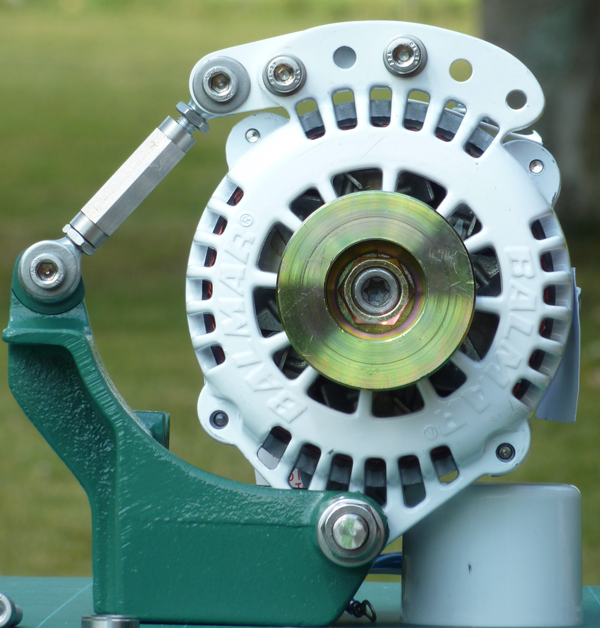

The first spacer in situ (this one is mild steel, not stainless):

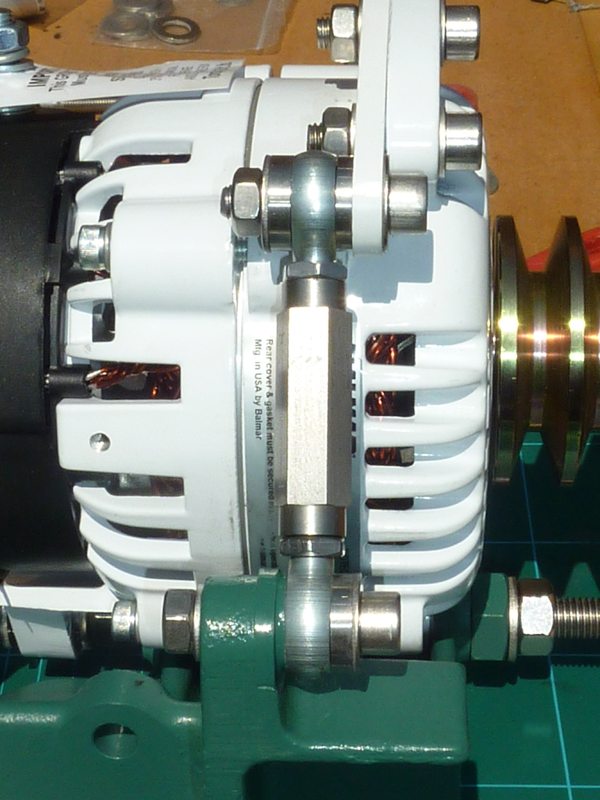

The final arrangement:

The adjustment range is quite small, but this is compensated for by having a selection of turnbuckle centres. Once I find the right one, I'll just keep that, and the next size up. The track-rod ends are clamped by the spacers onto the ball, so are free to rotate around it. However, the swivelling is restricted by ridge on the spacers. I gave up trying to make a rounded indentation on the stainless steel spacers, my lathe was not happy; I just did two steps at about 0.75mm and 1.5mm. The final depth was adjusted on a belt sander during fitting.